All

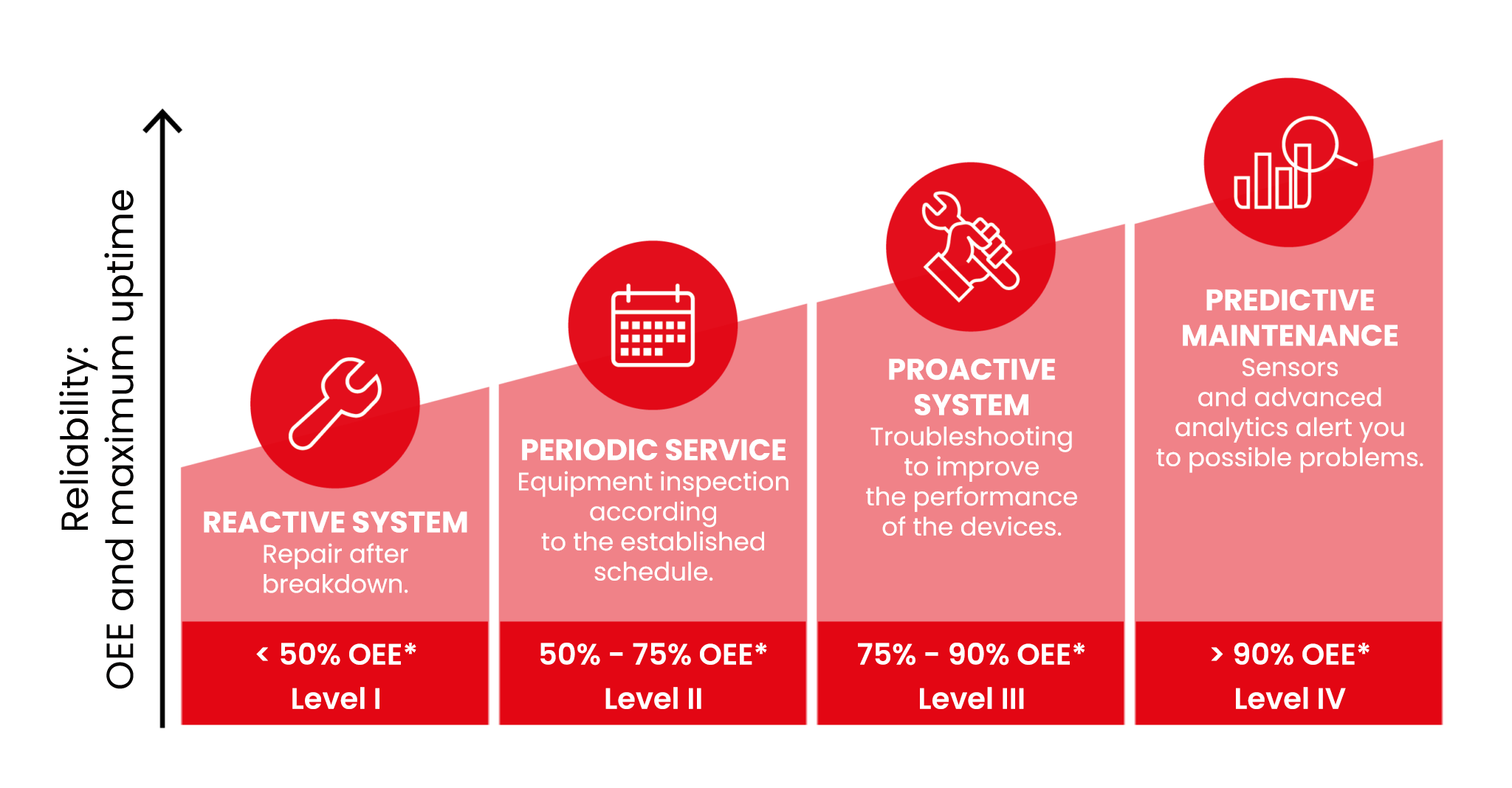

In a perfect world, reacting to a problem usually precedes its occurrence. But will it work out in real life? Yes, indeed, thanks to predictive maintenance, which is based on the Internet of Things. Industry 4.0 giants are leveraging this technology today, and it’s extremely profitable.

Back in 2016 or so, it was claimed that predictive industrial failure based on the Internet of Things (IoT) was a question of the near future. Estimates even pointed to a 40 per cent improvement in operational efficiency, all due to predictive asset maintenance alone.

We are in 2022 now, so it is a good time to review these predictions. Has the technology in question really brought about a revolution in the Fourth Generation Industry?

At the outset, it’s important to clarify what predictive maintenance (PdM) actually is. In the manufacturing context, it refers to the use of sensor data and artificial intelligence (AI) to detect failure patterns in machinery and its components. Using IoT, factory assets can be effectively and reliably monitored, and appropriate preventive action is taken even before a fault occurs. Monitoring by means of software can record data such as energy consumption, pressure or cycle time.

It sounds like a simple mechanism, doesn’t it? However, PdM is much more elaborate than it may appear. After all, it includes such complex activities as:

The answer is straightforward: no. The very idea of Industry 4.0 is based on automation, simplification, boosting efficiency, and removing obstacles. And predictive maintenance fits perfectly into this idea.

At present, something known as a life cycle is undergoing digital transformation. Instrumented and networked machines are providing more and more information about themselves, so predictive maintenance has simply become a natural consequence of technological development. Improvements in data collection and analysis have certainly made their contribution. Artificial intelligence techniques, including machine learning, have also played a significant role.

Predictive maintenance is most quickly implemented in areas which are associated with instant and measurable benefits. Example? Coupled with analytical technologies, IoT sensor systems allow to reduce the cost of maintaining some part of skilled personnel, especially when it comes to 24-hour operation. This was the case for Mitsubishi Electric Smart Condition Monitoring (SCM), which developed a system for the food industry. Real-time data was sent via Ethernet to a PLC for accurate monitoring and analysis in the cloud.

What are the other perks of using predictive maintenance?

Effective predictive maintenance means pure profit and concrete numbers. A large-scale IBM study found that the solution increases maintenance productivity by up to 28.3%. Downtime in 558 companies was reduced by more than 20%, while the average time needed for the return on investment was only 14.5 months.

Another IBM report shows a nearly 70 per cent drop in overall failures and a 25 per cent reduction in asset maintenance costs.

So let these figures speak for themselves. Especially when we talk about measurable results in Industry 4.0.